Magnetic Filtration

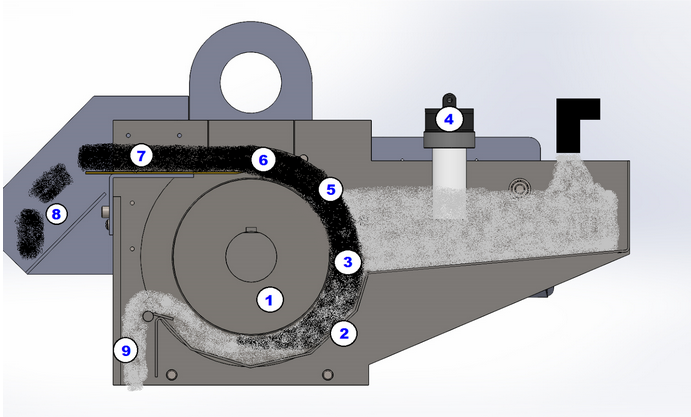

A correctly adjusted filter is designed for fully automatic operation. Dirty coolant entering the dirty fluid inlet trough of the Magnetic Filter flows across a solid magnetic drum. The drum is not rotating, so that the largest magnetic particles are attracted and held just at the entry to the discharge beneath the unit. As coolant flows against the drum, unlike a Separator, finer particles are attracted and held. A sponge-like cake is created, and this acts as a filter media to attract additional magnetic particles as well as non-magnetic particles such as wheel abrasives, tramp oil, and graphite.

When the discharge space is entirely filled with contaminant swarf, the level in the dirty fluid inlet trough rises. A Fluid Level Probe detects this rise and gives a signal to the control system. The drum is rotated only a fraction of an inch so that a small space is opened to allow the process to repeat.

- Magnets are arranged to create a 360° uninterrupted field

- Magnetic Particles are captured by the Field forming a Filter Matrix

- Filter Matrix functions as Filtration Media

- Fluidic Level Control monitors coolant level

- Matrix becomes blocked with Contaminants

- Spent Matrix is indexed out of Coolant Flow Path

- Contaminants deposited on to Scraper Blades

- Contaminants discharged

- Clean Coolant returns to the Process